BSB Custom-engineered separators have exclusive design and operational features which provide maximum efficiency throughout a long service life. The ones I used were 8-inch pipe 6 ft long with a dump capacity of 35 gallonsdump using two-stage floats.

Posted 06 June 2011 - 0819 PM.

. Up to 1440 psig. The conclusion will be made that blowcases will continue to play an important part in oilfield operations and that better understanding of blowcase Best Practices would be beneficial to industry. Features Benefits that Ensure Performance.

With regard to operations 3 and 4 they specify conditions at which the compression process. Digital Design program in the School of Art Design. Improved Blowcase Operation and Design by William G.

Designed to be integrated and included in a Spitzer Package or installed as a stand-alone piece of equipment. Improved Blowcase Operation and Design by William G. Improved blowcase operation and design pdf Posted on September 9 2021 The operating philosophy is when the level in blowcase reach setting level the dump sequence will start by means of using the discharge.

In my case that means I have to introduce another 5 to 10 psi differential between where I take the power gas from my compressor discharge piping and where I inject the condensate out of the blowcase back into it. As a result these components often condense in compressor gas coolers resulting in operational and environmental problems including frozen dump lines heavy tank vapor emissions and hydrates. Improved blowcase operation and design pdf By admin September 5 2020 The operating philosophy is when the level in blowcase reach setting level the dump sequence will start by means of using the discharge.

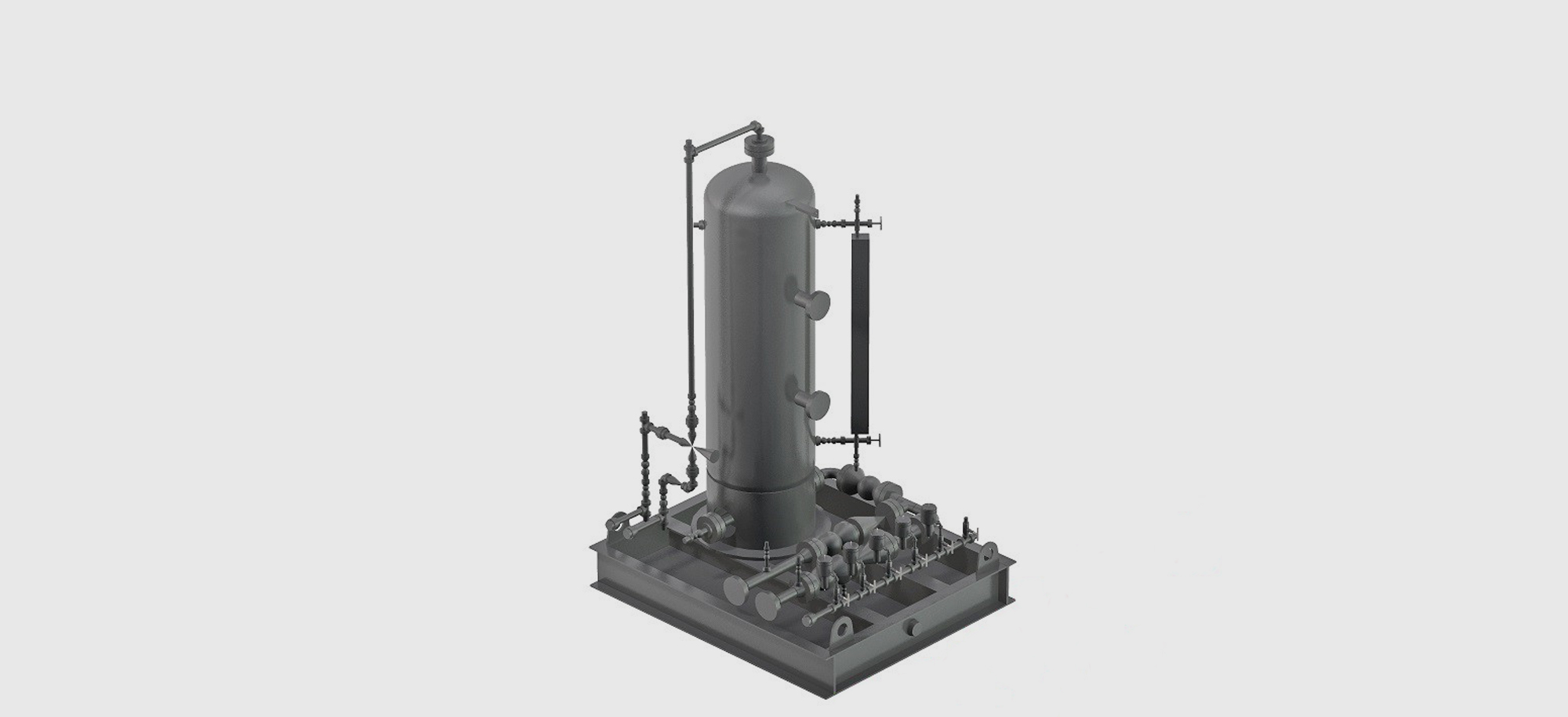

Oil from the Collection Vessel flows to the blowcase lower horizontal vessel on image. The blowcase outlet either with a check valve or another control valve which opens lets the power gas drive the liquids out. Hi all In one of our Projects I have a task of sizing the blow case.

Available as fully engineered custom units or Titan standard design. Improved Blowcase Operation and Design by William G. Designed for ease of operation with one controlling valve.

It also has drain piping which can return the fluids into the process which is. Improved Blowcase Operation and Design OnePetro. The supposition is made that blowcase operation although.

This is the only reference ive ever heard of that treats this equipment. BSB Custom-engineered separators have exclusive design and operational features which provide maximum efficiency throughout a long service life. BSBs proven strength and experience with high volume crude oil streams are unsurpassed and includes separation of foamy and or waxy crude oils using single vessel capacities of over 600000 barrels.

Our Tankless Facility design works this way. Up to 42 diameter. I looked at this problem in the early 90s and decided that I had to design my own vertical blowcase since there were no commercial designs available.

The well design generally consists of 2-78 tubing. But even Digital Design students will take some coding and computer science courses as they blend art and technology in their course of studies. ASME code stamped pressure vessel.

Oil from the production system enters the collection vessel upper horizontal vessel on image. Students more interested in writing the code and programming of video games may study Information Technology in the College of Computing Sciences. Discussing the advantages and disadvantages of small versus large volume blowcases.

Blowcases are mainly used for liquids which have noxious or dangerous qualities. 30 OD x 54 ss Horizontal vessel rated 350 psig 350F Based on 15mmscfd 10psi 350 bblday Utilizes 10 minute. With the very small dead volume at the top I had no problem handling 500 bblday.

This is the only reference ive ever heard of that treats this equipment. This is the only reference ive ever heard of that treats this equipment. Water Reinjection for Disposal in Erawan Field.

I do understand that blow case vessels are employed to dump the liquid by using high pressure gas normally from compressor discharge thereby removing the need of a pump. Calculating blowcase efficiency for two level control designs and 6. A blowcase is a small tank which acts as a receiving vessel for liquid drains or sample points.

After the oil enters the blowcase the blowcase is pressurized using natural gas from the system eg gas. Hidden text to space because of js weirdness. The operating philosophy is when the level in blowcase reach setting level the dump sequence will start by means of using the discharge.

Find Blowcase Design related suppliers manufacturers products and specifications on GlobalSpec - a trusted source of Blowcase Design information. Pneumatic or electrical controls. For blowcases in automatic operation the opening and closing of the blow valves is logged.

Spitzer is also a Certified Jatco Blowcase Dealer should the customer prefer that alternative. Tie in blowcase to suction line discharge line fuel gas supply. Spitzer designed Blowcases are used to collect low pressure liquids and then move them into a high-pressure system by using high pressure gas as a driving force.

I would be grateful if experts can guide me in the design. The blowcase has piping for some type of compressed gas usually natural gas or nitrogen. Blowcase separator totally self contained.

Designs rated from ANSI 150 up to ANSI 600 to meet your specifications.

Manufacturing Blowcase Pumps Pesco Inc

Blowcase Vessels Spitzerspitzer

0 komentar

Posting Komentar